Planning a commercial construction project requires a solid understanding of costs, and one of the most critical aspects is the concrete slab. Whether you’re building a warehouse, office complex, or retail space, estimating the cost of a concrete slab accurately is essential for budgeting and project success. This article dives deep into the factors influencing commercial concrete slab cost estimators, providing actionable insights and expert advice to help you make informed decisions.

Estimating the cost of a commercial concrete slab involves more than just calculating the price of materials. Labor, design complexity, location, and additional factors can significantly impact the overall budget. Understanding these variables will not only help you avoid unexpected expenses but also ensure the longevity and quality of your project. In this guide, we’ll explore everything you need to know about commercial concrete slab cost estimators and how to use them effectively.

From breaking down the components of a concrete slab to analyzing regional pricing trends, this article will equip you with the knowledge to navigate the complexities of commercial construction costs. Whether you’re a contractor, project manager, or property owner, this guide is designed to provide clarity and confidence in your decision-making process.

Read also:Understanding Mmsdose A Comprehensive Guide To Its Uses Benefits And Risks

Table of Contents

- Understanding Concrete Slabs in Commercial Projects

- Key Factors Affecting Commercial Concrete Slab Costs

- How to Use a Commercial Concrete Slab Cost Estimator

- Material Costs Breakdown

- Labor Costs and Expertise

- Regional Variations in Pricing

- Additional Costs to Consider

- Tips for Accurate Cost Estimation

- Common Mistakes in Cost Estimation

- Conclusion and Call to Action

Understanding Concrete Slabs in Commercial Projects

Concrete slabs are a fundamental component of commercial construction, serving as the foundation for floors, pavements, and other structural elements. They are typically flat, horizontal surfaces made from a mixture of cement, aggregates, water, and sometimes additives to enhance durability or performance. The thickness and design of a concrete slab depend on the intended use and load-bearing requirements of the structure.

In commercial projects, concrete slabs must meet specific standards to ensure safety and longevity. These standards are often dictated by local building codes and regulations. For example, industrial warehouses may require thicker slabs to support heavy machinery, while retail spaces may prioritize aesthetic finishes. Understanding these requirements is crucial for accurate cost estimation.

Concrete slabs can be categorized into several types, including suspended slabs, ground-bearing slabs, and post-tensioned slabs. Each type has unique characteristics and cost implications. For instance, post-tensioned slabs, which use steel cables to enhance strength, are more expensive but ideal for large spans. By familiarizing yourself with these options, you can make informed decisions that align with your project goals.

Key Factors Affecting Commercial Concrete Slab Costs

Several factors influence the cost of a commercial concrete slab. Understanding these variables is essential for accurate estimation and budgeting. Below, we’ll explore the primary factors that contribute to the overall expense.

1. Slab Thickness and Size

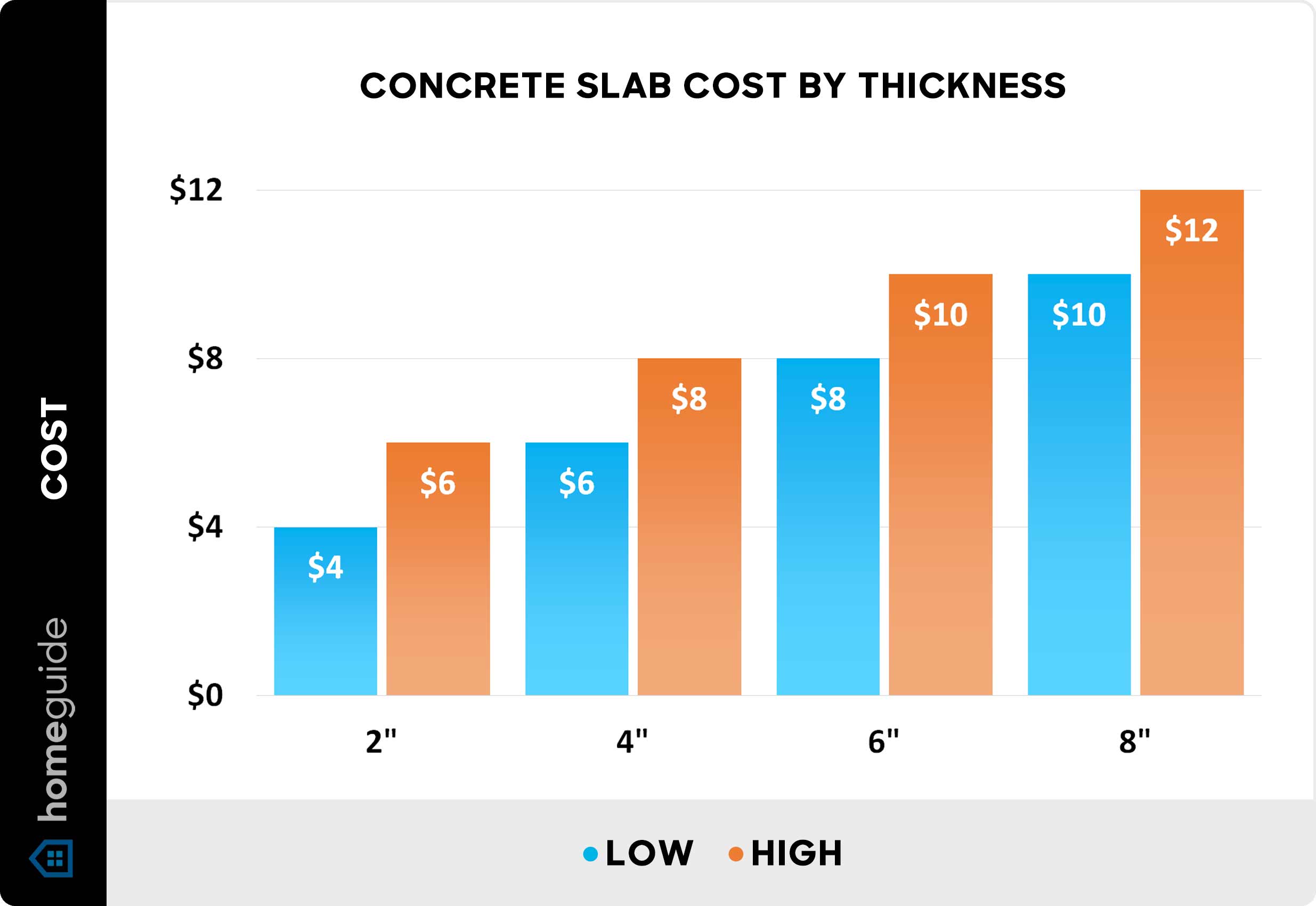

The thickness and size of the slab are directly proportional to the cost. Thicker slabs require more materials and labor, increasing the overall expense. For example, a 6-inch slab will cost significantly more than a 4-inch slab due to the additional concrete and reinforcement needed.

2. Type of Concrete Mix

The type of concrete mix used can also impact costs. High-strength concrete, which contains additional cement or additives, is more expensive than standard mixes. However, it may be necessary for projects requiring superior durability or load-bearing capacity.

Read also:Kirsten Too Sweet The Rising Star Taking The World By Storm

3. Reinforcement Materials

Reinforcement materials, such as rebar or wire mesh, add to the cost but are essential for structural integrity. The choice of reinforcement depends on the slab’s intended use and the expected load it will bear.

4. Site Preparation

Site preparation, including excavation, grading, and compaction, can significantly affect costs. Poor soil conditions may require additional measures, such as soil stabilization or the installation of a vapor barrier, further increasing expenses.

How to Use a Commercial Concrete Slab Cost Estimator

A commercial concrete slab cost estimator is a valuable tool for predicting expenses and planning budgets. These tools are often available online and provide a quick way to calculate costs based on project specifications. Here’s how to use them effectively:

1. Input Project Details: Start by entering the dimensions of the slab, including length, width, and thickness. Most estimators will also ask for details about the type of concrete mix and reinforcement materials.

2. Adjust for Regional Pricing: Labor and material costs vary by location. Ensure the estimator accounts for regional pricing trends to provide a more accurate estimate.

3. Include Additional Costs: Don’t forget to factor in additional costs, such as site preparation, permits, and finishing options. Some estimators allow you to add these expenses manually.

4. Review the Results: Once you’ve entered all the necessary information, review the results carefully. Compare the estimate with quotes from contractors to ensure accuracy.

Material Costs Breakdown

Material costs are a significant component of commercial concrete slab expenses. Below is a breakdown of the primary materials and their average costs:

- Concrete Mix: $100-$150 per cubic yard for standard mixes. High-strength mixes can cost up to $200 per cubic yard.

- Rebar: $0.50-$1.50 per linear foot, depending on size and grade.

- Wire Mesh: $1.50-$2.50 per square foot.

- Vapor Barrier: $0.10-$0.20 per square foot.

These costs can vary based on supplier pricing and regional availability. It’s essential to obtain quotes from multiple suppliers to ensure competitive pricing.

Labor Costs and Expertise

Labor costs are another critical factor in commercial concrete slab projects. The complexity of the project, the size of the slab, and the expertise of the workforce all influence labor expenses. On average, labor costs range from $3-$7 per square foot.

Skilled labor is essential for ensuring the quality and durability of the slab. Hiring experienced contractors may cost more upfront but can save money in the long run by preventing costly mistakes or repairs. Always verify the credentials and track record of contractors before hiring them.

Regional Variations in Pricing

Regional variations play a significant role in commercial concrete slab costs. Factors such as local labor rates, material availability, and transportation costs can cause significant price differences. For example, projects in urban areas may incur higher costs due to increased labor rates and logistical challenges.

To account for regional variations, consider consulting local contractors or industry reports. These sources can provide valuable insights into pricing trends and help you create a more accurate budget.

Additional Costs to Consider

Beyond materials and labor, several additional costs can impact the overall expense of a commercial concrete slab. These include:

- Permits: Building permits and inspections can cost several hundred to several thousand dollars, depending on the project’s size and location.

- Finishing Options: Polished or stained finishes can enhance the appearance of the slab but add to the cost.

- Site Cleanup: Removing debris and cleaning the site after construction is complete is an often-overlooked expense.

Accounting for these costs upfront can prevent budget overruns and ensure a smoother project execution.

Tips for Accurate Cost Estimation

Accurate cost estimation is crucial for the success of any commercial construction project. Here are some tips to help you achieve precision:

- Gather Detailed Specifications: Clearly define the project’s scope, including slab dimensions, materials, and finishes.

- Consult Experts: Work with experienced contractors and engineers to validate your estimates.

- Use Multiple Estimators: Compare results from different cost estimation tools to identify discrepancies.

- Include Contingency Funds: Allocate 10-15% of the budget for unexpected expenses.

Common Mistakes in Cost Estimation

Avoiding common mistakes can save time and money during the estimation process. Some frequent errors include:

- Underestimating Labor Costs: Failing to account for the complexity of the project can lead to inaccurate labor estimates.

- Ignoring Site Conditions: Poor soil quality or other site challenges can increase costs significantly.

- Overlooking Permits and Fees: These expenses are often forgotten but can add up quickly.

Conclusion and Call to Action

Estimating the cost of a commercial concrete slab is a complex process that requires careful consideration of multiple factors. By understanding the variables that influence costs and using reliable estimation tools, you can create a realistic budget and avoid unexpected expenses.

Whether you’re a contractor, project manager, or property owner, this guide provides the knowledge and resources you need to navigate the complexities of commercial concrete slab cost estimation. Take the time to research, consult experts, and plan thoroughly to ensure the success of your project.

We’d love to hear your thoughts! Share your experiences or ask questions in the comments below. For more insights into commercial construction, explore our other articles and resources. Don’t forget to share this guide with others who may find it helpful!